PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

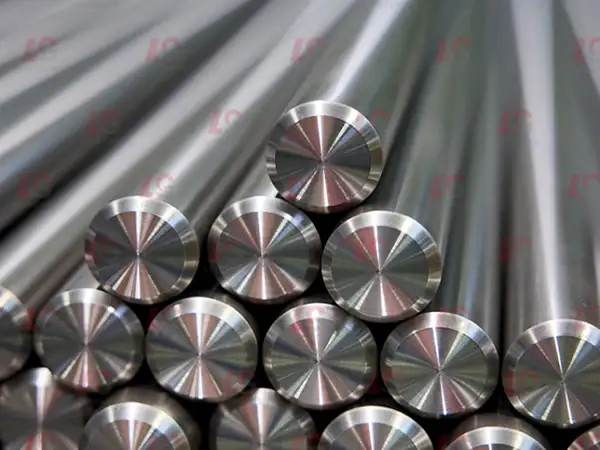

Mobile

303 grade stainless steel is also called 1.4305 stainless steel, and 303 grade is the easiest to process of all austenitic stainless steels. The machinability properties of the 303 grade are due to the presence of sulfur in the steel elements. Sulfur can improve machining, but it also reduces corrosion resistance and toughness. The corrosion resistance of the 303 type is lower than that of the 304 type, but the toughness is still as excellent as other austenitic grades.

305 stainless steel is an austenitic chromium-nickel stainless steel with a low work hardening rate. This low work hardening rate makes it suitable for many deep drawing applications. In order to minimize the earrings during the drawing process, the directionality introduced during the cold rolling process must be kept to a minimum.

310S is an austenitic stainless steel that combines excellent high temperature performance with good ductility and weldability. It is usually used for high temperature applications because its high chromium and nickel content provides solid corrosion resistance, excellent oxidation resistance and excellent strength at temperatures up to 2100 °F. Due to its high chromium and nickel content, it is superior to 304 or 309 stainless steel in most environments.

316Ti(UNS S31635) is a titanium stabilized version of 316 molybdenum-containing austenitic stainless steel. 316 alloys are more resistant to general corrosion and pitting/crevice corrosion than traditional chromium-nickel austenitic stainless steels such as 304.

317L is a low-carbon austenitic stainless steel containing molybdenum. More chromium, nickel and molybdenum are added to obtain better corrosion resistance and increase the resistance to sulfurous acid, acetic acid, formic acid, citric acid and tartaric acid. Resistance to chemical attack. Due to its low carbon content, 317L also provides resistance to sensitization during welding, as well as higher creep, rupture stress and high temperature tensile strength. It is non-magnetic in the annealed state, but may become slightly magnetic after welding.

321(UNS S32100) is a titanium stabilized austenitic stainless steel with good general corrosion resistance. It has good intergranular corrosion resistance at a chromium carbide precipitation temperature of 800-1500 °F(427-816°C). The alloy is resistant to oxidation at 1500 °F(816°C) and has higher creep and stress rupture properties than the 304 and 304L alloys. It also has good low temperature toughness.

330 is an austenitic nickel-chromium-iron-silicon alloy with excellent oxidation and carburizing properties up to 2200 °F and high strength. The high nickel and chromium content of the alloy provides excellent oxidation resistance and carburization, and the silicon content further improves the oxidation resistance of the alloy. The ultra-high nickel content of 34 to 37% of the alloy 330 also provides high resistance to chloride stress corrosion cracking and embrittlement due to sigma phase precipitation in most furnace atmospheres. The alloy 330 also has a low coefficient of expansion, excellent ductility and high strength.

347 is a stable austenitic chromium steel, containing niobium, which can eliminate carbide precipitation, thereby eliminating corrosion during the year. 347 is stabilized by the addition of chromium and tantalum, and provides higher creep and stress rupture properties than alloys 304 and 304L, which can also be used for sensitization and exposure to corrosion problems during the year. The addition of niobium also makes the 347 alloy have excellent corrosion resistance, even better than the 321 alloy.