PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

A533 Pressure Vessel Steel Plate

ASTM A533 Boiler vessel plates are manganese-molybdenum and manganese-molybdenum-nickel alloy steel plates suitable for welding pressure vessels. Often with quenching and tempering heat treatment, that is, quenching and tempering state supply. ASTM A533 boiler vessel steel is available in five different strength grades: Class A, Class B, Class C, Class D, and Class E. There are three levels of each category: level 1, level 2 and level 3.

A516 Pressure Vessel Steel Plate

ASTM A516 grades: 55, 60, 65, 70, is a high-quality boiler and pressure vessel steel, very suitable for low to medium temperature applications. The material is widely used by industrial boiler and pressure vessel manufacturers that provide manufacturing support for the oil, gas and petrochemical industries. The steel has good weldability and excellent notch toughness.

A537 Pressure Vessel Steel Plate

ASTM A537 Boiler vessel plates are heat treated carbon manganese silicon steel plates used in pressure vessel fabrication. ASTM A537 Boiler Container Plate has 3 grades, namely Grade 1, Grade 2, and Grade 3.

JIS G3103 P296GH/P355GH/P235GH Pressure Vessel Steel Plate

JIS G3103 Boiler Container Plate is a hot-rolled plate of carbon steel and molybdenum alloy steel for Chinese and high temperature boilers and pressure vessels. The main grades of JIS G3103 boiler vessel steel are: SB410, SB450, SB480,SB450M and SB480M.

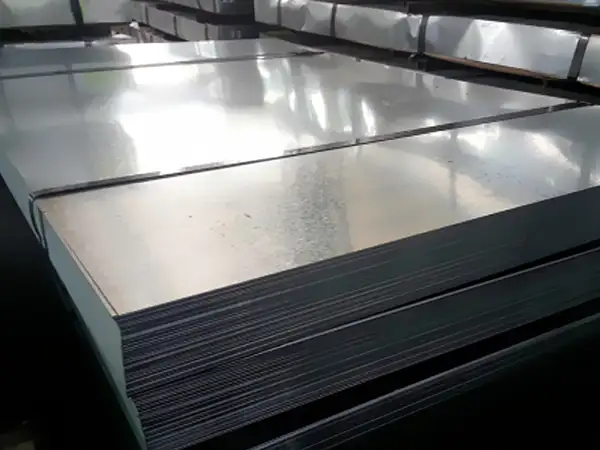

Galvanized steel is a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So EG steel is also known as cold galvanized steel. Through electrolytic galvanizing, a uniform and dense zinc layer is finally formed on the surface of the steel, but the mechanical properties of the material are still maintained. Electrogalvanized steel is usually sold in coil or sheet form. EG coil is a kind of material that can be cut, slitted and profiled for other purposes.

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Prepainted Galvanized Steel Sheet

When steel components are used to make more complex finished products, they can be galvanized before the product is assembled. This is called pre-galvanizing, or "pre-galvanizing". It may also be referred to as "in-line", "continuous" or "rolled" galvanizing. Essentially, steel components (such as sheets or wires) are galvanized using an automated process before they are cut to size.

The material of DX51D galvanized sheet is a non-ferrous alloy with zinc as the matrix and other elements. The main alloying elements are aluminum, copper, magnesium and so on. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and resistance to atmospheric corrosion.

According to the manufacturing process, it is divided into cast zinc alloy and deformed zinc alloy. The commonly used casting zinc alloy is zinc-aluminum-copper-magnesium alloy, which has good casting process performance, and the cooling rate has little effect on the mechanical properties. They are mainly used in the manufacture of mechanical parts, toys, decorations and household appliances.